Induction heating systems revolutionize automotive dent removal with precise electromagnetic field heat generation, avoiding damage to surrounding materials. They offer faster, effective alternatives to conventional painting or bodywork processes, minimizing cosmetic imperfections and ensuring consistent heat distribution. These systems are transforming paintless dent removal (PDR), enhancing vehicle bodywork repairs and streamlining auto repair procedures for both shops and car owners. Future trends predict continued evolution in induction heating technology, increasing versatility for various vehicle makes and models.

Induction heating, a cutting-edge technology, is transforming the paintless dent removal (PDR) industry. This non-invasive method utilizes electromagnetic fields to heat and reshape metal without damaging the surface finish. In this article, we explore the fundamentals of induction heating technology, its numerous advantages in PDR, and common applications. We also delve into future trends, highlighting how induction heating systems are revolutionizing automotive repair and setting new standards for precision and efficiency.

- Understanding Induction Heating Technology

- Advantages of Induction Heating Systems in PDR

- Common Applications and Future Trends

Understanding Induction Heating Technology

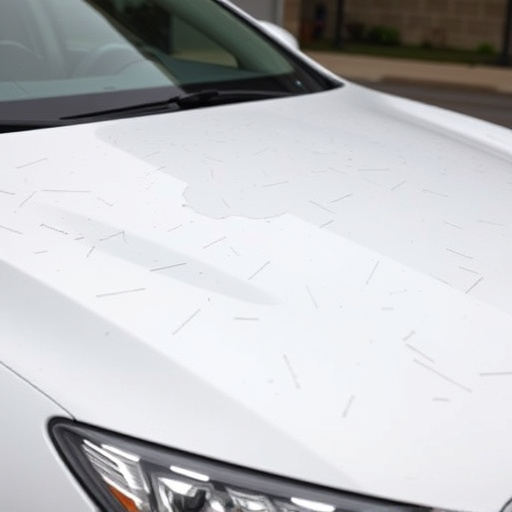

Induction heating technology has emerged as a game-changer in the automotive industry, particularly for paintless dent removal procedures. This innovative approach utilizes electromagnetic fields to generate heat within metal, making it a precise and controlled process. Unlike traditional heating methods, induction heating systems offer several advantages. They enable efficient and localized heating, ensuring minimal thermal impact on surrounding materials, which is crucial for maintaining the integrity of vehicles’ outer panels during dent repair.

By inducing eddy currents in metallic components, these systems can deliver targeted heat to specific areas affected by dents or dings. This precision is particularly beneficial for complex vehicle collision repairs and tire services, where access to tight spaces is often challenging. The technology’s ability to quickly and evenly heat metal facilitates the reversal of dents, restoring vehicles to their pre-damage condition without the need for invasive painting or bodywork procedures.

Advantages of Induction Heating Systems in PDR

Induction heating systems have revolutionized paintless dent removal (PDR) procedures, offering numerous advantages over traditional methods. One of the key benefits is their precision and control. These systems allow technicians to heat specific areas of a vehicle’s panel with exacting accuracy, enabling them to effortlessly remove dents without damaging surrounding surfaces. This level of precision is particularly valuable when dealing with intricate automotive designs, ensuring that even the most complex dents can be corrected efficiently.

Furthermore, induction heating systems provide consistent and uniform heat distribution, which is crucial for effective dent removal. This technology enables faster and more efficient repair processes, reducing the time required for bumper repair or luxury vehicle repair tasks. Unlike some traditional methods, induction heating minimizes the risk of color fading or other cosmetic imperfections, resulting in superior-quality finishes. With their advanced capabilities, induction heating systems have become indispensable tools in the automotive repair services industry, setting new standards for PDR techniques.

Common Applications and Future Trends

In the realm of automotive aesthetics and repair, induction heating systems have emerged as a game-changer for paintless dent removal (PDR). Common applications include vehicle bodywork repairs, where their precise heat application facilitates metal manipulation without damaging the surrounding paintwork. This non-invasive approach is particularly valuable for car body repair shops, offering a faster and more cost-effective alternative to traditional painting methods.

Looking ahead, future trends suggest that induction heating technology will continue to evolve, further refining PDR processes. As advancements in materials science and engineering occur, these systems are expected to become even more versatile, catering to diverse vehicle makes and models. This ongoing innovation promises to streamline auto repair near me procedures, benefiting both repair shops and car owners seeking high-quality, efficient vehicle bodywork solutions without the need for extensive repainting or body panel replacement.

Induction heating technology has revolutionized paintless dent removal (PDR) by offering efficient, precise, and non-invasive solutions. The advantages of induction heating systems in PDR are clear, from faster cycle times to reduced energy consumption and minimal heat impact on surrounding materials. As the industry continues to evolve, further exploration of these innovative systems will drive progress, ensuring faster and more sustainable vehicle repair processes. By embracing induction heating technology, professionals can stay at the forefront of the ever-changing landscape of PDR.